“Physical Contact Push-Pull Technology for Fiber Optic Connectors” recognized as IEEE milestone. Promoting ferrules around the world through manufacturing.

Optical fiber connectors are one of the essential components of optical fiber communications. The advancements in connector designs have made connection and disconnection of fiber optic cables much simpler. The push-pull type Subscriber Connector (SC), also known as “Square” or “Standard” Connector, that is currently in widespread use was developed by Nippon Telegraph and Telephone Corporation (NTT) and introduced for commercial use in 1986. This achievement has now become a world-renowned “IEEE Milestone”. The Institute of Electrical and Electronic Engineers (IEEE) is the world’s largest professional society related to the field and recognized the “Physical Contact Push-Pull Technology for Fiber Optic Communications, 1986” developed by NTT as a Milestone in technological achievement.

Orbray started manufacturing ferrules, essential parts for fiber optic communications, in 1980. In particular, development of zirconia ceramic ferrules for PC connections by extrusion molding started in 1987, and we achieved high-precision mass production by injection molding in 1989. When the IEEE Milestone was approved, Orbray received a letter of appreciation and a small plaque from NTT for our efforts and contribution to globalization of fiber optic communications through the development and manufacture of easy-to-use ferrules.

Table of contents [close]

- 1. Award for outstanding technical achievements from the world’s leading authority

- 2. Technologies that led to fiber optic communication

- 3. Promoting mass produced, high-precision zirconia ceramic ferrules

- 4. Supporting development and reliability of fiber optic communication through ferrule manufacturing

Award for outstanding technical achievements from the world’s leading authority

The IEEE (commonly referred to as “I triple E”) is the world’s largest professional organization for electrical and electronic engineers, with 400,000 members from over 160 countries. It publishes papers, holds international conferences, formulates standards, and plays the leading role in many fields such as computers, biotechnology, robotics, telecommunications, electronics, power, and aviation.

The IEEE Milestone was established in 1983 to shed light on outstanding technological achievements and raise public awareness and recognition of the engineers that created them. Since its beginning over 25 years ago, the IEEE Milestones have honored many breakthrough technological innovations in the electrical, electronic, IT, and communications fields for their contributions to the development of society and industry.

Past Milestones include invention of voltaic batteries, the telephone, the Edition Institute, and other technologies and facilities on which modern society currently benefits greatly. The newest Milestones recognized in the 20th century include transistors, the Apollo Lunar Modules, computers, and the birth of the internet. In Japan, the Tokaido Shinkansen (bullet train) electronic quartz wristwatches, and the Nobeyama 45-m Radio Telescope have won Milestone recognition.

Technologies that led to fiber optic communication

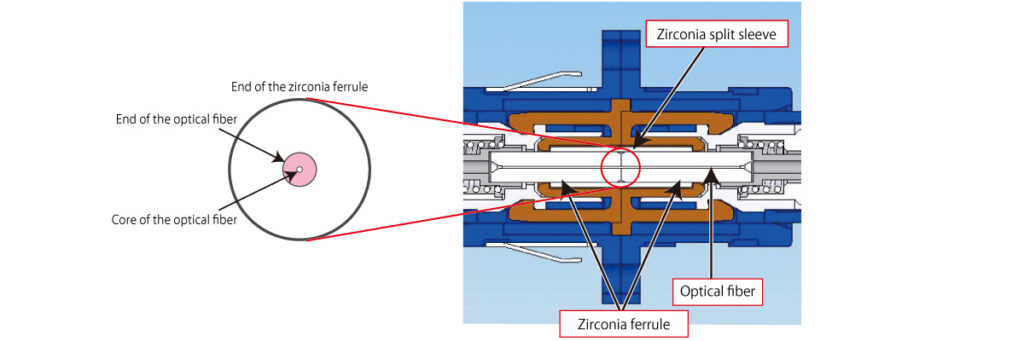

In physical connections, the terminal ends of the ferrules are polished into a convex spherical shape, and the vertices of the joining fibers are pressed against each other to make the optical fiber connection. There is little reflection and loss, and refractive index matching agents are not needed.

Fiber optic manufacturing technology was developed to practical application levels by the 1970s in the United States, and research for widespread use began shortly therafter. Optical fibers are several dozen to several hundred micrometers in diameter. The core through which the light travels is as small as 10 micrometers. Therefore, accurate connection with no deviation or gap is essential. At the time, ferrules with tiny holes drilled axially into which the connecting fibers were inserted were developed as connection components.

Before the advent of the physical contact connections, ferrule ends were polished flat. This increased the possibility of gaps forming between the fibers. Refractive index matching agents to suppress light reflection at the terminal surfaces were also required. With the completion of the fiber optic grid in the mid-1980s, and the raising popularity of optical communications, optical connectors with less reflection and loss during connection were required. The physical connection for optical fibers was developed to meet these needs.

In addition, in order to connect more optical cables to a device, high-density mounting of optical connectors was required. To achieve this, it was necessary that connections could be made without the need for grasping the connector and turning it, as in screwing it in place. The SC connector with the push-pull mechanism allowed connections to be made by simply pushing the ferrule into the receiver, and could be easily be pulled out with one hand by operating the fastening clip. Optical fiber connectors continued to be developed in this way, and physical connectors that use push-pull type ferrules are still in widespread use around the world today.

Promoting mass produced, high-precision zirconia ceramic ferrules

Orbray continues to be deeply involved in the promotions of push-pull type physical contact fiber optic connections.

Using gem bearing processing technology used in watchmaking, Orbray started developing ferrules in the late 1970s. We started manufacturing alumina ceramic ferrules by extrusion molding in 1980. However, one problem with the alumina ceramic ferrules was its weakness. When being pressed to make the physical connection, the edge of optical fiber insertion hole would often become chipped. The alumina ceramic was changed to zirconia ceramic, which had higher toughness.

However, zirconia ceramics are so tough that they are very difficult to grind, and achieving the extremely high accuracy required by fiber optics was a great challenge. After repeated improvements in processing equipment and methods, we started manufacturing mass production of zirconia ceramic ferrules by extrusion molding in 1987.

As fiber optic communication became more commonplace, the demand for connectors also increased, and the need to manufacture larger quantities at lower costs became more pressing. Extrusion technology of the time was still inaccurate, resulting in products with large variations in dimensions. Therefore, it was necessary to extrude the parts larger than required, and then grind and polish down to meet the required dimensions. This added to manufacturing time and cost. As a solution to this problem, Orbray changed course to use injection-molding to manufacture its ferrules. It was commonly understood at the time that injection molding was also an inaccurate and expensive method for manufacturing ferrules. With injection molding, it is possible to shape the parts very close to the final dimensions. So, if injection accuracy could be improved, labor for final finishing could be greatly reduced.

However, injection of zirconia compound into the mold with uniformity and homogeneity high enough to produce satisfactory parts required very high processing capabilities. By using specially configured injection molding technology and lots of trial and error, we succeeded in manufacturing zirconia ferrule by injection molding. Mass production started in 1989.

Supporting development and reliability of fiber optic communication through ferrule manufacturing

As fiber optic communications continued to increase, the production of zirconia ceramic ferrules also increased. In order to keep pace, Orbray introduced robotics to the injection molding process. In-house production of the zirconia ceramic compound began in 1996. In-house production of core pins, a consumable component of injection molding dies, started in 1999. This led to greater production volume and better cost management. Even in the 2000s, we continue to streamline the production process by increasing productivity and precision.

The development of the fiber optic connection using a simple and cost-effective push-pull physical contact mechanism contributed greatly to the widespread adoption of fiber optic communication around the world. IEEE recognized this accomplishment by designating this a “Milestone” technology. For Orbray, it was a great honor to be so deeply involved in this work. We are humbled to have received the letter-of-appreciation and plaque.

In making our ferrules, we have always listened closely to the needs of our customers, and responded by creating custom-made technical solutions and craftsmanship. We will continue to use our knowledge and past experiences to strengthen the production of high precision, high efficiency ferrules in order support the development and stable operation of fiber optic communications.

-

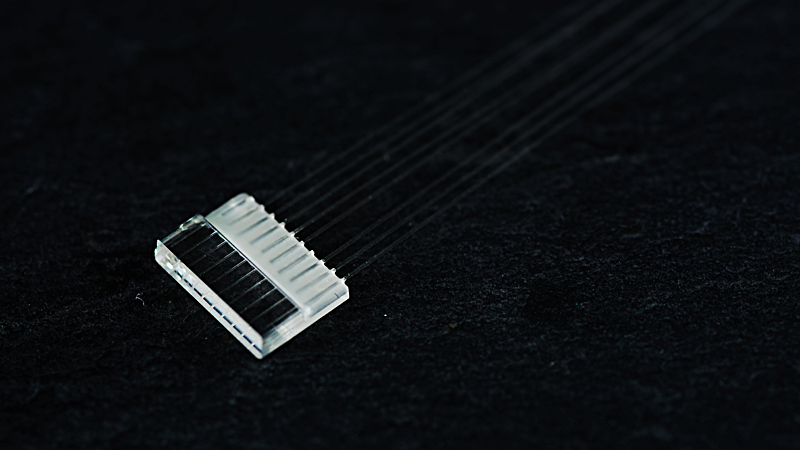

What is an Optical Fiber Array? - Connecting devices with optical waveguide elements are indispensable for next-generation high-speed, large-capacity optical communications.

-

Optical Fiber Current Sensors

-

What are optical interconnects and fiber optics?

-

Lensed Fibers: Brief introduction to the functions and manufacturing methods

-

Lensed fibers used in submarine cables

-

All About Lasers: How they work, their properties, and their uses