Brushless motor vs brushed motor: The features of the Orbray brushless motor.

What is the difference between a brushless motor and a brushed motor?

Explaining the features of the Orbray brushless motors.

Table of contents [close]

What is a brushless motor?

A brushless motor is a motor in which the mechanical parts that come into contact with each other, such as commutators and brushes, have been removed.

In conventional motors, a commutator and brushes are used to mechanically reverse the positive and negative electrical charges that drive the motor, but the friction of the brushes against the commutator causes those parts to wear out, as well as other problems, resulting in a short service life for the motor.

With the widespread use of semiconductors, electronic circuits are able to produce the magnetic fields that cause the motor to rotate, thereby eliminating the need for commutators and brushes.

The resulting brushless motor has a longer life than motors using mechanical commutators.

Find more information about our brushless motor here:

Differences between a brushless motor and a brushed motor

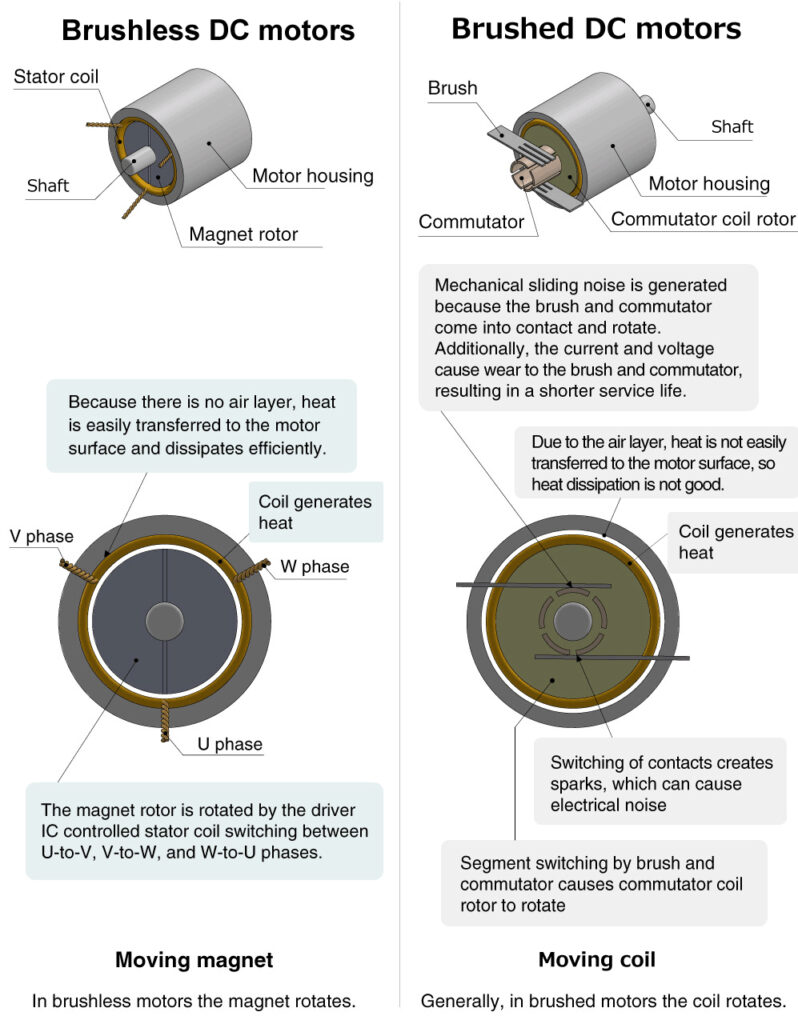

1: Heat dissipation

In a coreless motor with a brush, there is a gap (layer of air) between the rotating coil and the motor housing, so heat generated by energization is not easily transferred to the outside..

In contrast, in a brushless motor, the magnet rotates and the coil is fixed in close contact with the outer core, so the heat from the coil is easily transferred to the motor surface, resulting in high-efficiency heat dissipation.

If the temperature inside the motor rises too much, the magnet may be demagnetized and performance may deteriorate.

For this reason, brushless systems with high heat dissipation are more advantageous for higher power uses.

2: Large current/high power

In a brushed motor, the commutator on the rotor side and the brush on the stator side slide while energizing. If a large current is applied, the electrical contact may melt and fail, so there are limitations on power input.

In a brushless motor, the driver circuit controls the externally-energized coil, so there is no contact point, and this along with high heat dissipation means a large current can be applied to the motor.

3: Mechanical noise

Brushed motor

A brushed motor generates a mechanical sliding noise due to the contacts rubbing against each other. In addition, when the contacts switch with rotation, sparks are generated at the contacts, which causes electrical noise.

Brushless motor

A brushless system has no contacts and therefore no noise source.

A brushless motor has better heat dissipation, higher maximum rotation speed, longer life, and less noise than a brushed motor. However, unlike a brushed motor, which can be operated simply by connecting it to a power source, a brushless motor needs a control circuit for operation. Selection of the appropriate control circuit depends on whether the motor has a sensor that detects the rotor position.

Brushless servo driver (Reference): Motor Drive Circuit SSD06-R5A / SHSD24-01A

Characteristics of the Orbray brushed motor

Comparing the generally slotted armature type (with iron core) brush motors with Orbray's coreless brush motors, our brush motors are characterized by smaller coil leakage inductance and better commutation conditions because the armature winding is not in a slot.

Since there is little variation in magnetic resistance, cogging (torque pulsation caused by the iron core) is eliminated, which means the motor produces very little electrical noise.

Characteristics of the Orbray brushless motor

A non-contact motor allows extremely high power and a long service life, ensuring high reliability.

Orbray's brushless motor has a slotless structure, without slots in the stator.

Such slots (gaps in the magnetic core) can cause cogging (rotation pulsation) because the magnet attracts the convex portion between the slots.

This cogging produces vibration and noise, and affects rotational accuracy and smoothness.

Orbray's brushless motor has cup-like coils installed in the core, and the rotor's magnet is placed inside.

As a result, the coil and the magnet are subjected to uniform magnetic attraction regardless of the position of the rotor, thus enabling smooth rotation without cogging.

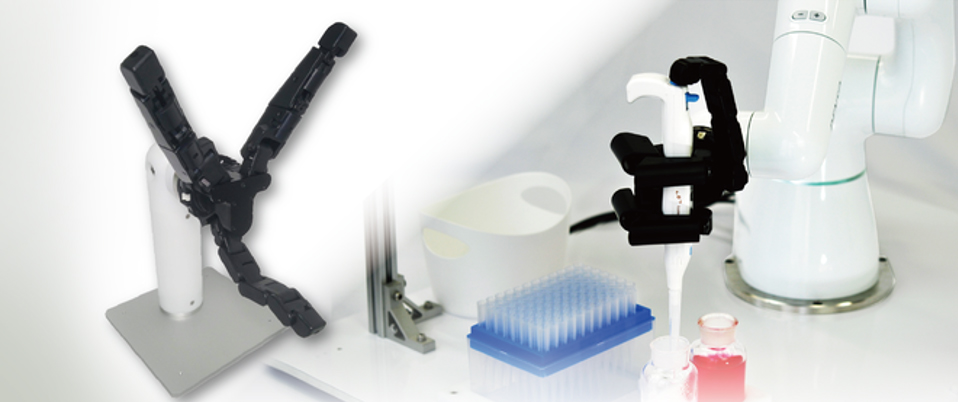

The Orbray micro brushless motor is especially suitable for applications such as robots and medical equipment that are particularly sensitive to factors such as torque and require a long service life.

Product lineup

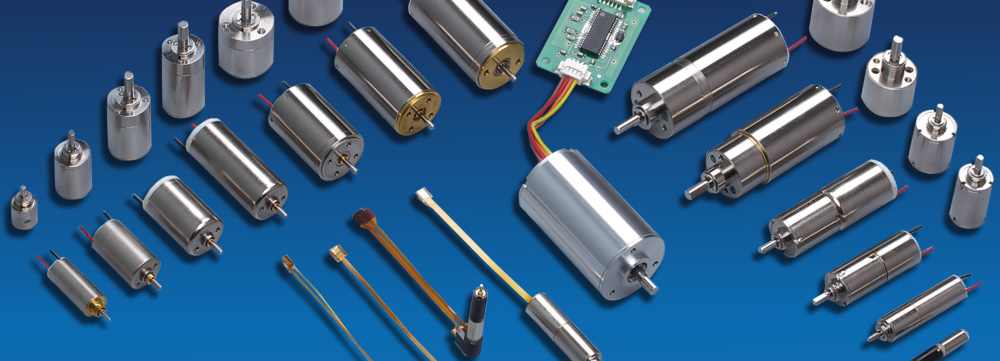

At Orbray, we utilize the technology we have cultivated through the development of the world's smallest motors, and we offer a brushless motor with a wide product lineup starting from φ4mm.

The compactness, torque, service life, quietness, and low level of vibration of our brushless motor offer solutions for applications that require high performance in a limited space, such as portable equipment, robots that need quick response time and delicate movements to effectively communicate, special astronomical telescopes that require actuators to be placed in a narrow pitch, and joint actuation in robotic hands for precise movements.

Extending the life of a brushless motor

The B4S series motor in our brushless motor lineup is a high-torque motor employing a 4-pole magnet.

By changing the magnet from the usual 2 poles to 4, the effective magnetic flux area is increased, improving the torque constant and reducing the current consumption.

The improved mechanical time constant further increases the ease of starting the motor and adjusting its speed.

The B4S series also uses ball bearings as standard, and high torque is supported by the efficacy and reliability of the design.

Reference: Introduction to Motor Technologies. Yuji Akiyama, Kogyo Chosakai Publishing Co., Ltd. 1999