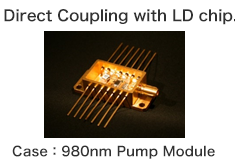

Lensed Fibers are required for the manufacturing of Butterfly Type and Optical Pump Modules. By our

processes of discharging, etching, lapping, polishing and grinding the end face of the fiber, we can

configure the Lensed Fiber form similar to an actual lens shape suitable for connection and improved

coupling efficiency with LD and PD Modules.

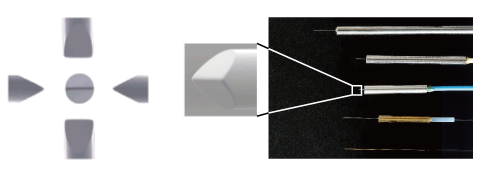

We have several lens fiber types, CLF (Cylindrical Lensed Fiber) and SLF (Spherical Lensed Fiber) and we

can also combine the process to include Metallization, AR-Coating, Metal Tube and FBG with the lensed

fiber assembly.

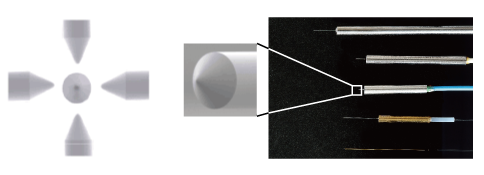

All of our Lens Fibers are custom products designed per customer specification requirements and processed

based on our extensive experience resulting in an optimum design to fulfill your needs.

Lensed Fiber Processing Technology

- Select fiber tip configuration and beam pattern.

- Unique fiber tip polishing process utilizing own process equipment.

- Reducing fiber core offset by well established processing.

| Fiber Tip Configration | Beam pattern | Applications |

|---|---|---|

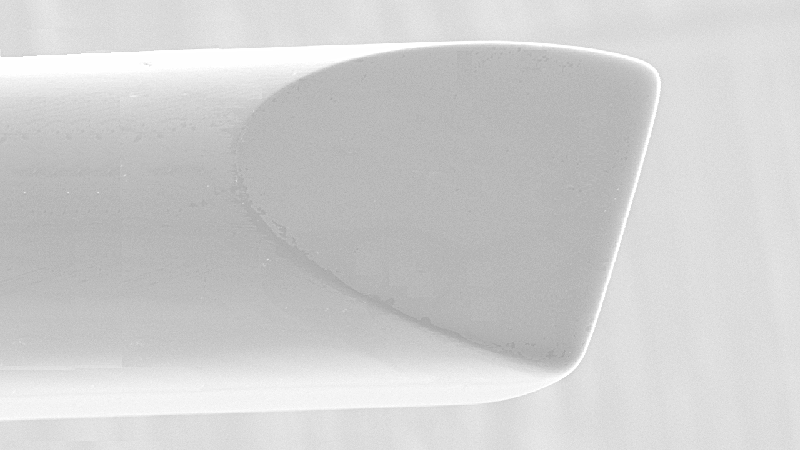

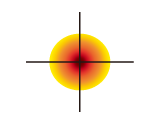

Spherical Lensed Fiber(SLF)Spherical Lensed Fiber(SLF)

|

|

|

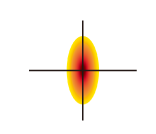

Cylindrical Lensed Fiber(CLF)Cylindrical Lensed Fiber(CLF)

|

|

|

Biconical Lensed Fiber(BLF)Biconical Lensed Fiber(BLF)

|

|

|

Applications

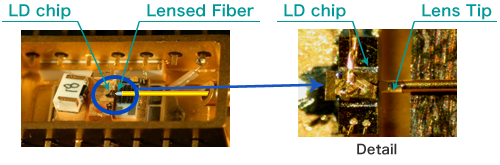

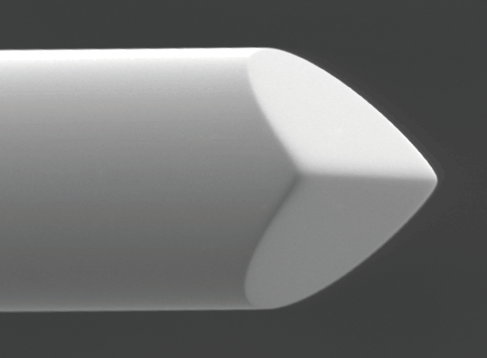

Spherical Lensed Fiber

The best lensed fiber for coupling with circular beam patterns

Spherical Lensed Fiber (SLF), the end face tip of the optical fiber is processed into a conical or circular shape by our lapping, grinding and polishing techniques so that the apex matches exactly the core of the fiber. SLFs have excellent coupling efficiency for light with circular beam patterns. They are often used for optical communication LD modules, optical waveguides, silicon wire waveguides, output to PDs, and for illuminating very micro areas.

Applications

|

1310m, 1550nm LD Coupling |

LD Module |

|

OWG, Si-wire Waveguides |

Optical Probes |

|

Output to PD |

Optoelectronic Integrated Circuits(OEIC) |

|

Microscopic region Lighting |

Gas Sensors |

|

VCSEL Connections |

Methane Gas Sensors |

Spot Irradiation |

Specifications

|

Lens Radius R |

3≦R≦20 [μm] |

|

Fiber Strip Length Ls |

5≦Ls≦30 [mm] |

|

Fiber |

SMF, MMF, PMF, Speciality Fiber |

|

Taper Angel θ |

50 - 140, Special: 5 - 15, 30 [deg.] |

Options

|

AR Coating |

980, 1310, 1480, 1550 nm Reflectance Max: 0.3% |

|

Metallization |

Chemical Plating Ni, Au / Physical Sputtering Ti, Pt, Au |

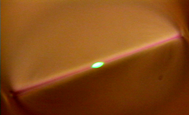

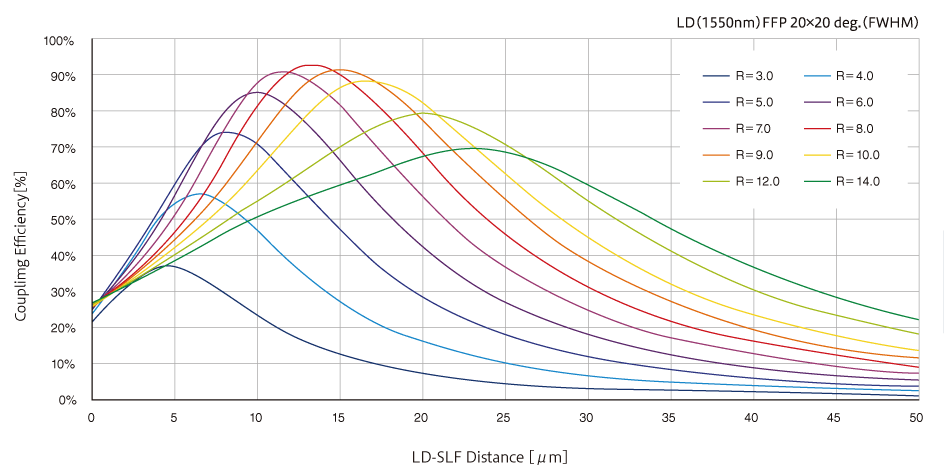

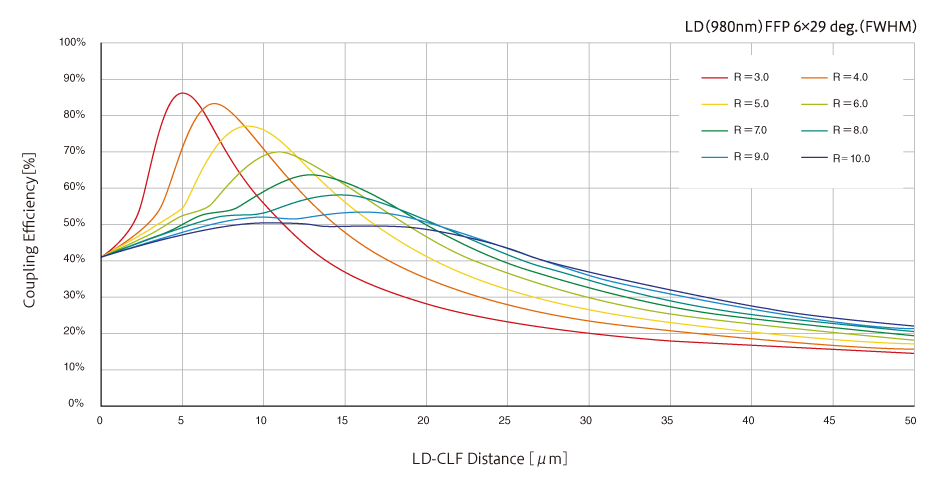

The Coupling Efficiency of SLF

The Coupling Efficiency profile

Cylindrical Lensed Fiber

The best lensed fiber for coupling with oval beam patterns

Cylindrical Lensed Fiber (CLF), the end face tip of the fiber is processed into an oval shape by our lapping, grinding and polishing techniques so that the apex matches exactly with the core of the fiber. CLFs have excellent coupling efficiency for light with oval beam patterns.They are often used for optical communication LD modules, optical waveguides, silicon wire waveguides, output to PDs, and for illuminating very micro areas.

Applications

|

1480nm LD Coupling |

Amp LD Module, High Power LD Module(Fiber Laser, Medical) |

|

Visible Light etc. |

Integrated Tunable Laser Assemblies(ITLA) |

|

OWG, Functional Waveguides |

FIber Optic Gyros |

Specifications

|

Fiber |

SMF / MMF / PMF / Speciality Fiber |

|

Lens Radius R |

3≦R≦20 [μm] |

|

Fiber Strip Length |

5≦Ls≦30 [mm] |

|

Taper Angel θ |

50 - 140 [deg.] |

Options

|

AR Coating |

980, 1310, 1480, 1550 nm Reflectance Max. 0.3% |

|

Metallization |

Chemical Plating Ni, Au / |

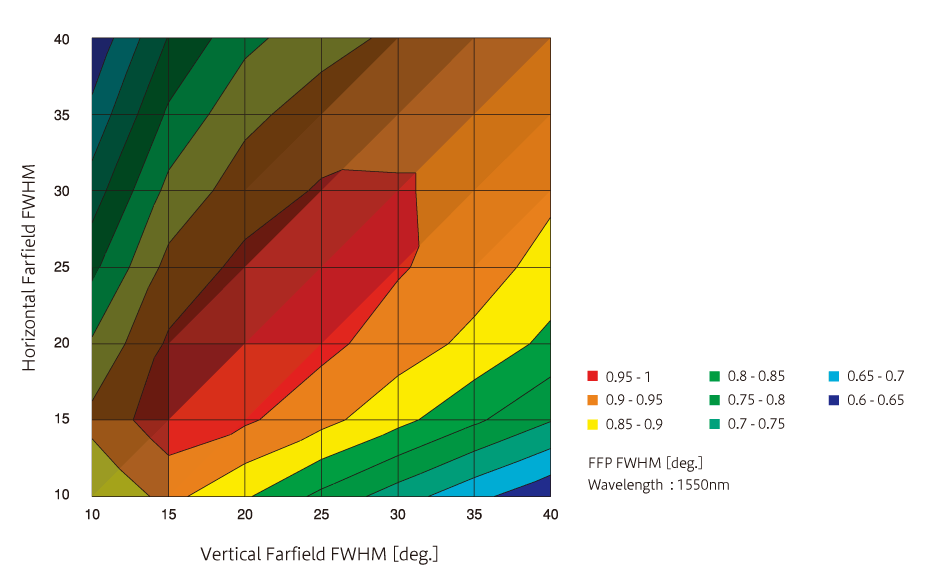

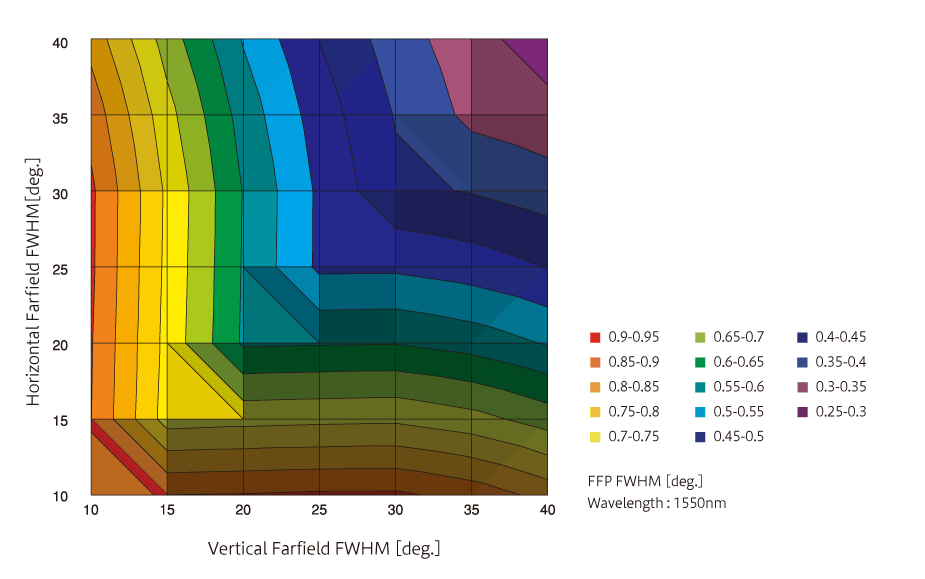

The Coupling Efficiency of CLF

The Coupling Efficiency profile

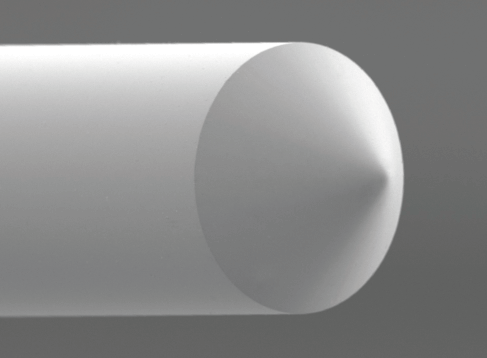

Biconical Lensed Fiber

The best lensed fiber for connection with elliptical beam light patterns

Biconical Lensed Fibers(BLF) are created by taking the oval fiber shape of the Cylindrical Lensed Fiber(CLF) and further cutting equivalent incline planes on the orthogonal planes, creating a pyramid-like shape on the end face tip of the fiber. Each axis acts as a lens by adding curvature to a semi-cylin-drical shape, and by changing the curvature of each, corresponding to the long axis and short axis of the elliptical beam pattern. BLFs are used in LD optical amplifiers and optical waveguides.

- Optical direct coupling to LD aspect ratio is typically 2:1

- High Coupling Efficiency

- Assembly for 1310, 1480 and 1550nm LD etc.

Applications

|

1480nm LD Coupling |

Amp LD Module |

|

Visible Light etc. |

High Power LD Module |

|

OWG, Functional Waveguides |

Specifications

|

Fiber |

SMF, MMF, PMF, Speciality Fiber |

|

Lens Radius R |

3≦R≦20 [μm] |

|

Fiber Strip Length |

5≦Ls≦30 [mm] |

|

Taper Angel θ |

50 - 140 [deg.] |

Option

|

AR Coating |

980, 1310, 1480, 1550 nm Reflectance Max: 0.3% |

|

Metallization |

Chemical Plating Ni, Au / |