Better Lifestyle through

Availability of Electricity

Hard, wear-resistant Sapphire Bearings allow highly accurate wattmeter readings.

Since our foundation, we have considered our company to be a family.

As a family, every staff member continues to pursue creativity, productivity, and made-to-order technology for our customers,

and to promote traditional Japanese craftsmanship that will contribute to society.

Hard, wear-resistant Sapphire Bearings allow highly accurate wattmeter readings.

Accurate time-keeping becomes possible with Jewel Bearings for watches.

Namiki produces low-cost, long-life Phonographic Styli, with record-breaking sales worldwide.

Origin of the company nameAt the time of our company's founding, our main product was jewel bearings that were made of hard materials. The company thus incorporated into its name the word "adamant," meaning "extremely hard." The word is derived from the Greek "adamas," which came to denote "diamond." Processing such materials is our core technology.

Development of unbreakable Crystal Glass helps watches to become an accessory used every day instead of only on special occasions.

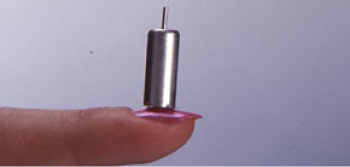

The world's smallest Micro Coreless Motor (10mm in diameter) contributes to the invention of the portable cassette player.

The world's first Vibration Motor adds a new function to mobile phones.

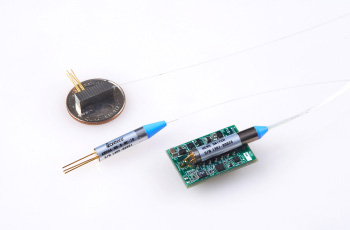

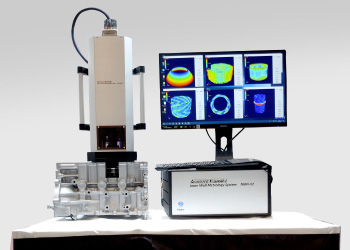

Micron-level processing of Optical Communications Parts supports reliable high-speed networks and broadband internet.

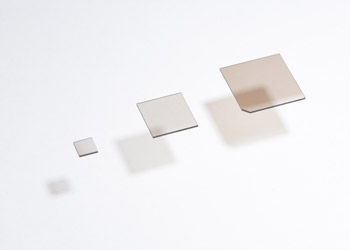

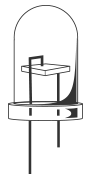

Growth of Single-Crystal Sapphire and micron-level polishing technology allow production of environmentally friendly LEDs.

With the world's smallest Micro Coreless Motor (0.9mm in diameter), catheter and endoscopic procedures become faster and more accurate.