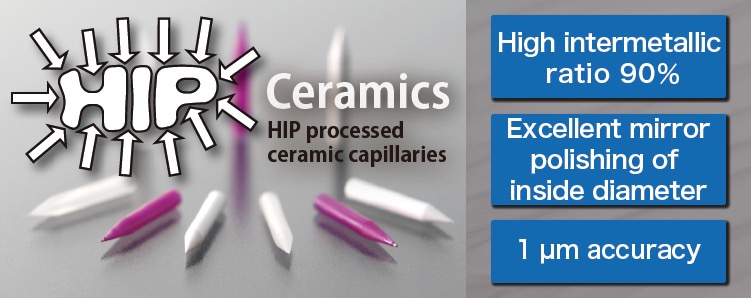

High precision capillary produced with by HIP processing and polishing technology

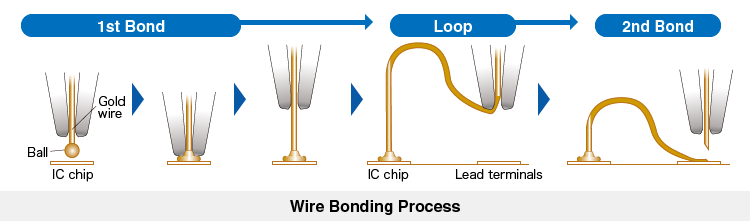

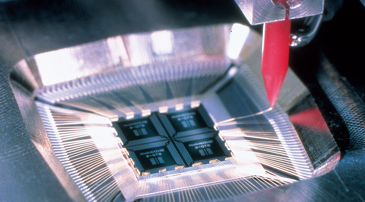

Capillaries are tools used in wire bonding machines to connect IC chip electrodes and lead terminals with wires.

Our company designs capillaries according to bonding specifications, and manufactures them using high quality materials.

[For wire bonding, a gold wire is used through the center hole of the capillary]

As shown in the figure, the gold ball is bonded to the electrode by the ultrasonic force applied from the bonding machine to the capillary, load, and the heat of the bonding stage. After that, a loop is formed and the wire joined to the lead terminal. During this process, the tip shape, accuracy, and surface condition of the capillary are very important.

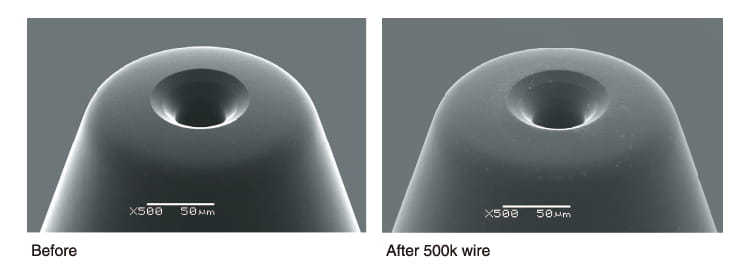

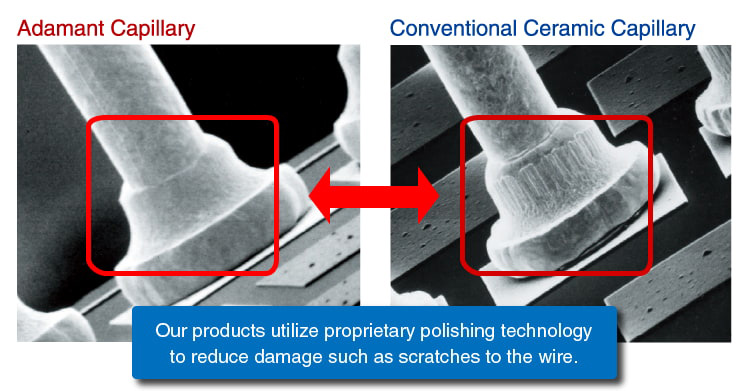

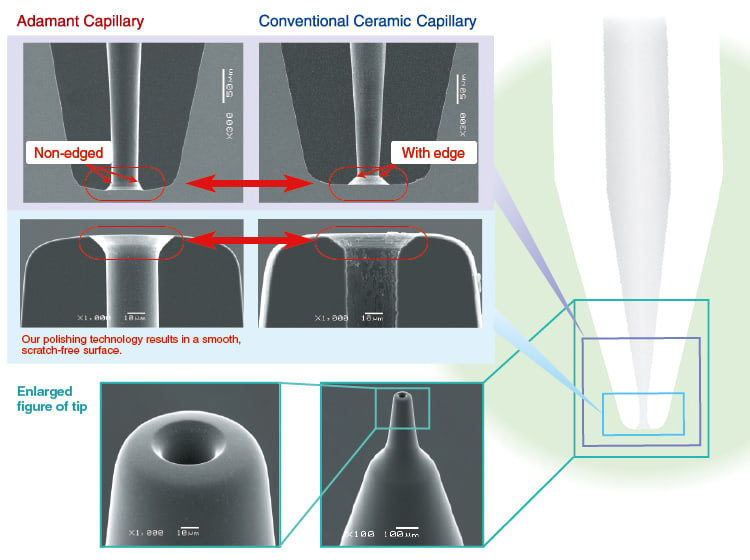

Because the loop shape is formed by the wire passing through the capillary in accordance with the movement of the capillary, it is also important to polish the inner diameter in order to prevent damage (scratches) to the wire and variations in loop height.

Our ceramic capillaries are HIP processed, which reduces individual differences that affect quality. They are highly trusted by customers in, as an example, the automotive industry which has required higher reliability in recent years.

Our single-crystal ruby capillaries are the only product of their kind in the world. The inner surface is mirror polished to prevent the wires (gold, silver, copper, alloy) from clogging.

We offer other custom items to quickly provide products that satisfy customer needs.

Features

- Removal of residual pores by HIP treatment; densification

- Prevents disconnection by improving the intermetallic ratio

- Superior mirror polishing of internal diameter enables a smooth bonding process

- High precision custom made

High precision capillary produced with HIP processing and polishing technology Suitable for automotive applications

Ceramic Capillary

Further Information

Our Ceramic Capillaries are manufactured by our Injection Molding Technology which is the same technology used in the mass production of our ferrules and sleeves used for the Optical Communication Industry. An excellent concentricity property has been achieved, which reduces the hours of operation significantly at the time of replacement due to the elimination of an alignment process. A longer capillary life span and a higher wear resistance has been achieved by using Zirconia Toughened Alumina Ceramic with a stronger hardness than the standard Alumina Ceramic. We can also accommodate a DLC (Diamond Like Carbon) Coating for an extended life span.

The function of Ceramic Capillaries is to allow a thin and brittle gold wire through at very high speeds. The Capillary shapes are required to be smooth and accurate for any bonding process. We polish the capillaries with high precision processing technology cultivated by the manufacturing of our Zirconia Ferrules.

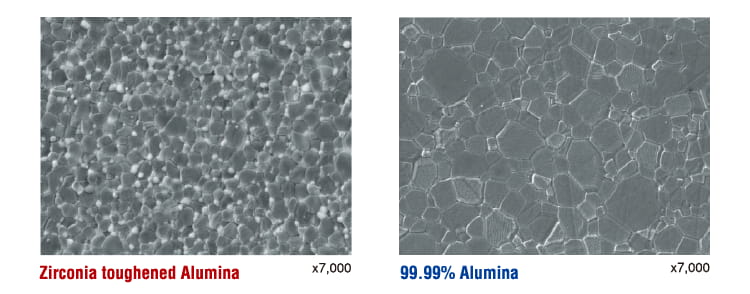

Material Characteristics

Longer capillary life span, adopting zirconia toughened alumina ceramic

Longer capillary life span and higher wear resistance have been achieved by zirconia toughened alumina ceramic with stronger hardness than the standard 99.99% aluminaceramic, and our unique process to increase hardness.

| Zirconia toughened Alumina | 99.99% Alumina | |

|---|---|---|

| Bending Strength | 1,700 (N/mm2) | 820 (N/mm2) |

| Hardness Vickers | 1,900 (HV) | 2,000 (HV) |

| Density | 4.3 (g/cm2) | 3.98 (g/cm2) |

| Average Grain Size | ≤0.5μm | ≤1.2μm |

| Color Appearance | White | White |

Our strict quality control from the raw materials to the finished products allows cost reduction and competitiveness.

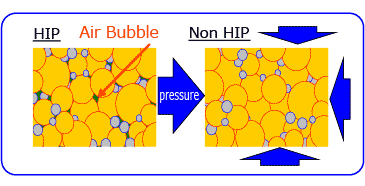

HIP Processing Additional HIP Treatment (Hot Isostatic Pressing)

In the HIP process, air bubbles generated between material particles are removed by applying high temperature (1000 ° C or more) and isotropic high pressure (1000 atm or more) to the object to be treated. (For reference, pressure at a sea depth of 6000 m is 600 atm.)

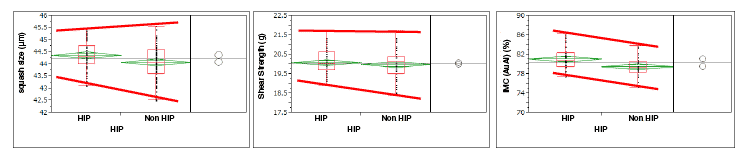

As a result, capillaries are densified and homogenized, and individual differences are reduced, and during bonding, the mashed ball diameter, shear strength, and intermetallic ratio are improved.

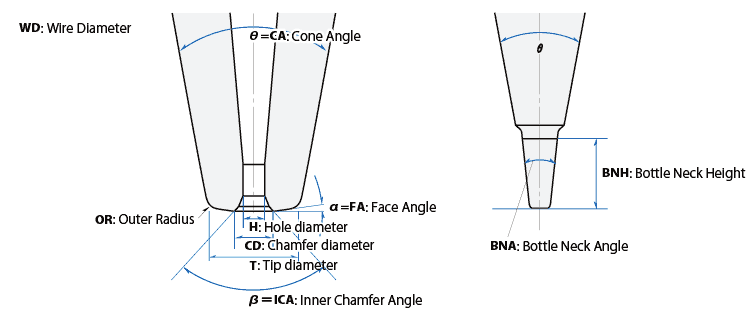

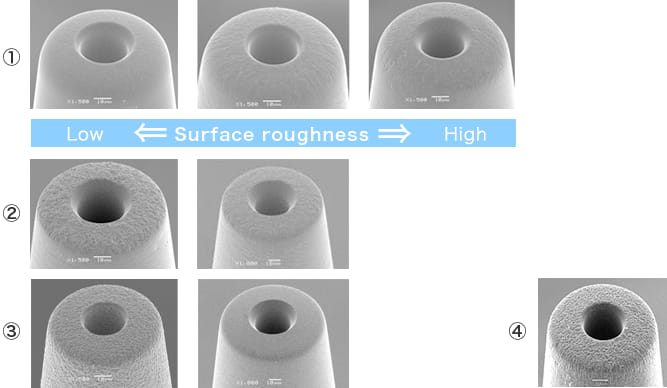

Capillary Shape

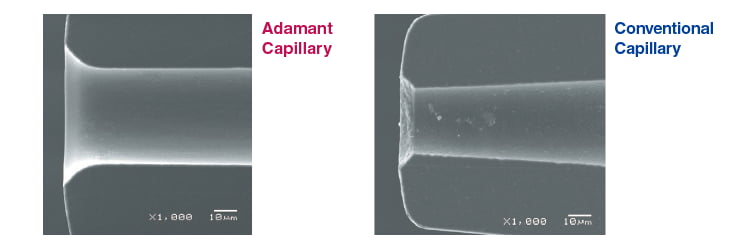

Reduce the damage to gold wire, the rare of contamination accumulation and wire breaking, achieved by the untapered straight hole with amooth and homogenerous surface.

And smooth geometry from chamfer to hole assures the stable bonding process.

Converentional capillaries sometimes have the tapered hole or rough surface, which causes the damage to the ball, the contamination accumilation and the wire breaking. Gentle transmutation from hole to tip through chamfer made by fine polishing reduces the damage to the wire and enable the stable bonding process.

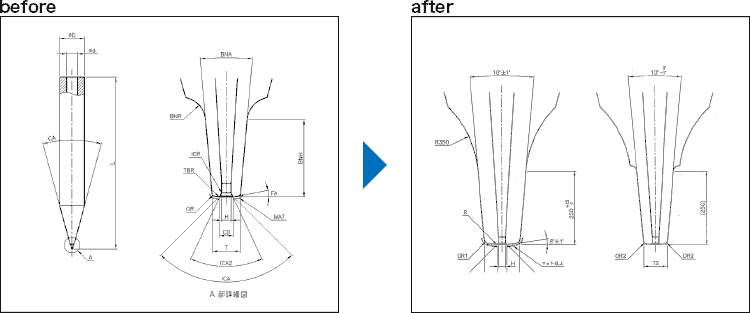

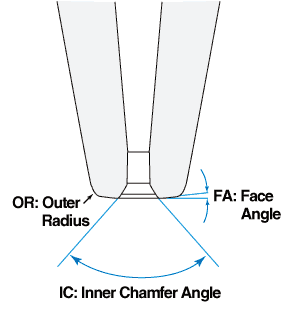

Capillary abbreviation list

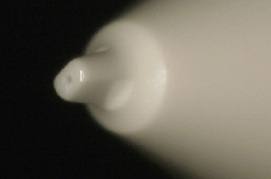

Create the ideal ball shape

Increase capillary durability by polishing the peripheral area of bottle neck with our unique and high precision process technology.

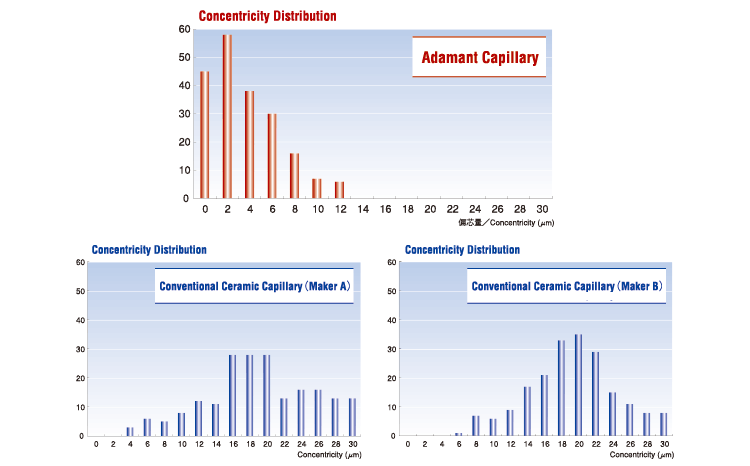

Concentricity

Excellent hole concentricity enables easy replacement procedure

With our unique precision process technology cultivated by the production of ferrule for optical communication, the excellent concentricity property has been achieved, which reduces the hours of operation significantly at the time of replacement due to the elimination of alighnment process.

Bonding Characteristics

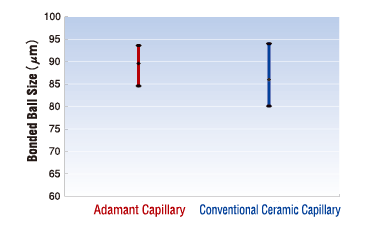

Superior bonding characteristics are derived from the smooth and stable ball shape

Bonded ball size

Bonded ball size is affected by Wire Diameter (WD), Hole (H) and Chamfer Diameter (CD). The uniform and stable ball shape is possible with the accuracy of the smooth chamfer geometry and the excellent hole concentricity.

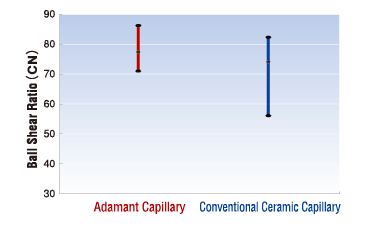

Ball shear ratio

This parameter is affected by WD, CD, pad substrate, mashed ball diameter and ball contact area. The satisfactory level of force and strength is committed by the stable geometry of chamfer.

Stitch bond

Important parameters affecting stitch bond are Tip diameter (T), Outer Radius (OR) and Face Angle (FA). Sufficient stitch bond on normal WD is achieved by the stable tip geometry, the tighter hole concentricity to T and the gentle OR.

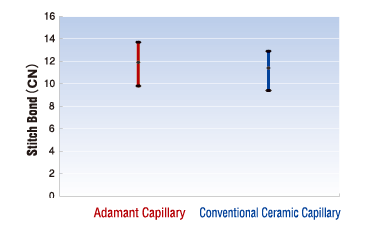

Special matte processing for ceramic capillary

Special mat processing is processing to roughen the surface of the specified part.

By roughening the surface, aspects such as wettability of the adhesive and plating strength can be improved.

In the ceramic capillary, the strength of 2nd bonding can also be improved by improving the grip force.

Considering compatibility with the bonded material, there are 4 types of mat construction methods.

- 1) Physical roughening

- 2) Blast treatment

- 3) Chemical treatment

- 4) Our proprietary processing method

Case study

Side-cut capillary

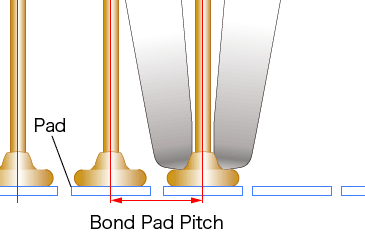

As devices become smaller and with higher density, narrow packages are increasing.

We propose a side cut capillary for narrow bond pitch with high bonding strength in order not to touch nearby wires and obstacles.

Catalog

Capillaries are selected based on the size and pitch of the bond pad to which the gold wire is bonded. (Bond pad pitch (BPP) = distance between the centers of two adjacent bond pads).

As semiconductor products become smaller, the bond pad pitch becomes narrower, requiring capillaries with greater precision.

Orbray is expanding its lineup in response to this need for smaller semiconductor products.

Ceramic Capillary

Standard Type Catalog

BPP:140∼150μm

Ceramic Capillary

Fine Pitch Series Catalog

BPP:60∼100μm

Ceramic Capillary

Uitra Fine Pitch Series Catalog

BPP:40∼50μm

Compatible Series

Orbray's high quality compatible capillary. Custom-made correspondence is possible.

| Part NO. | IC Inner Chamfer Angle |

FA Face Angle |

OR[μm] Outer Radius |

|---|---|---|---|

| AN-1 | Double120° - 80° | 8° | STD |

| AN-2 | Double120° - 80° | 8° | STD |

| AN-3 | Double90°-50° | 0° | Large |

| AN-4 | Double90°-50° | 0° (Narrow flat surface) |

Large |

| AN-5 | Double120°-90° | 0° (Narrow flat surface) |

Large |

| AN-6 | Single120°(IR) | 8° | STD |

| AN-S | custom | ||

(μm/mil)

Ceramic Capillary

Compatible Series Catalog

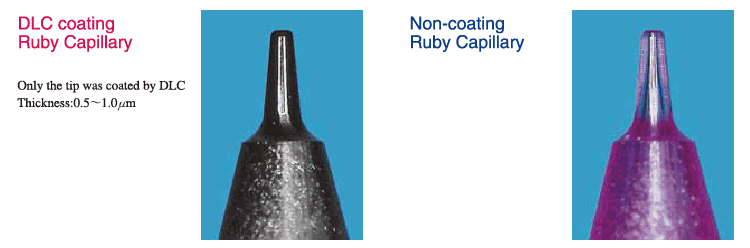

We supply the only single crystal ruby capillary in the world

Ruby Capillary

Further Information

Ruby Capillaries can maintain their form because of the high hardness of the material after a Wire Bonding Application. Our Ruby Capillaries can be used repeatedly because of our Gold Wire Washing Coat Process which is attached to the Ruby Capillary Surface.

The function of Ruby Capillaries is to allow a thin and brittle gold wire through at very high speeds. The Capillary shapes are required to be smooth and accurate for any bonding process. We manufacture the capillary hole diameter with a high precision processing technology by using a Laser Irradiation Process and a polishing process by using a diamond powder.

Material Characteristics

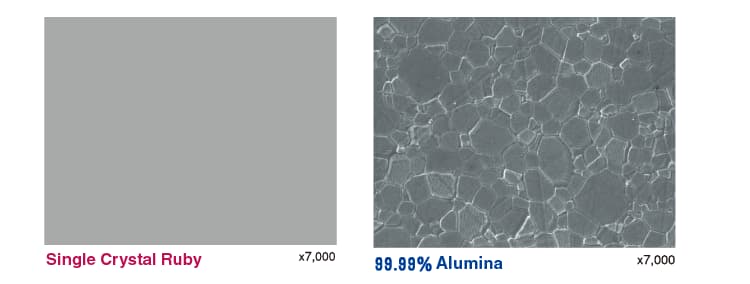

Excellent smoothness of single crystal ruby capillary prevents the damage and contamination accumulation of gold wire.

Our ruby capillary is made from single crystal ruby. Since the surface smoothness is superior to standard 99.99% alumina ceramic capillary, the damage of gold wire is reduced. In addition, the hardness is suitable to bottleneck form.

| Single crystal ruby | 99.9% Alumina | |

|---|---|---|

| Bending strengh | 1,026 (N/mm2) | 820 (N/mm2) |

| Hardness vickers | 2,000 (HV) | 2,000 (HV) |

| Density | 3.99 (g/cm2) | 3.98 (g/cm2) |

| Average grain size | Single crystal | ≤1.2μm |

| Color appearance | Red | White |

Our strict quality and production control from the raw materials to the finished products allows cost reduction and competitiveness.

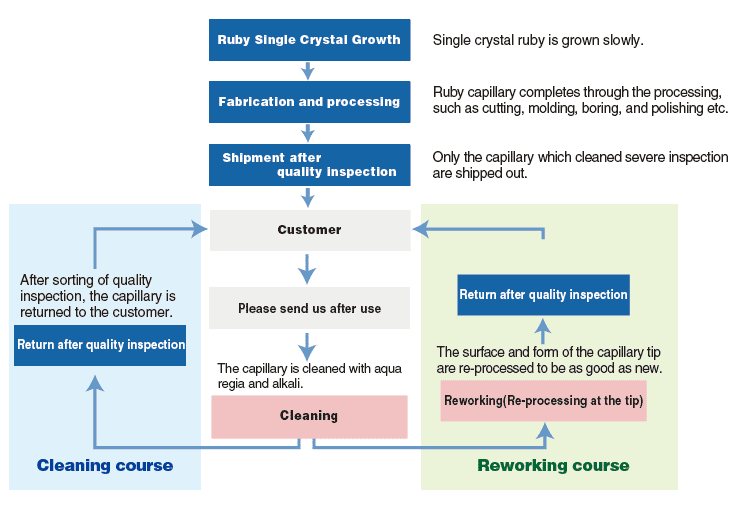

Rework and Cleaning for Reuse

By adoption of single crystal ruby which is excellent in chemical resistance, repetition of rework and cleaning for reuse of the capillary become possible. Ruby capillary is thus envernmental-friendly product.

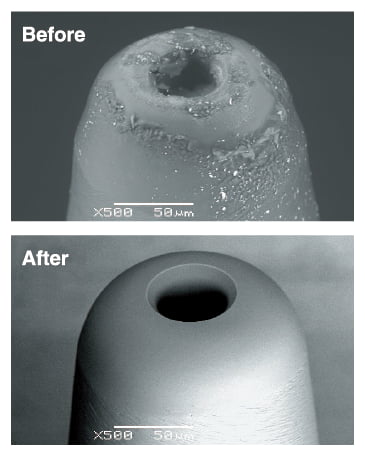

Cleaning for reuse

At the cleaning process, aqua regina and alkali remove adhesion of gold and carbide, respectively. Chemical residue doesn't adhere to the single crystal ruby capillary, so damage of gold wire can be eliminated. Because the capillary seldom has got bruises, it can be repeatedly used only by cleaning. We clean and inspect the capillary responsibly, so the quality is promised ans good as new products.

Rework

Rejected capillary can be re-new as reworked capillary with re-polish and re-processing onto the capillary tip. Reworking (re-processing at the tip) of capillary can be repeated until it becomes unfitted form for wire bonding. By using reworked capillary, the cost and environmental load can be reduced.

Life Cycle of Ruby Capillary

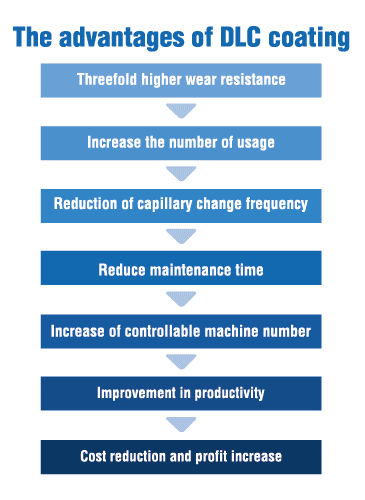

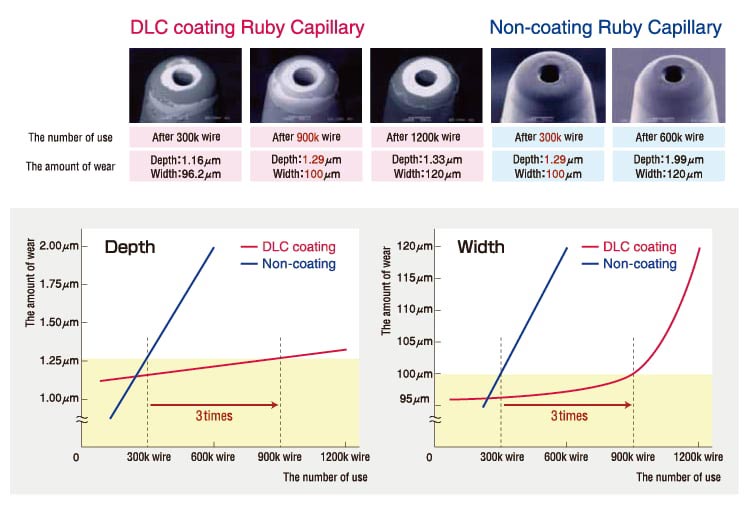

Narrow pitch. Adaptation to the low-temperature bonding. DLC (Diamond Like Carbon) coating achieve excellent wear resistance and threefold longer life span.

Recently, higher wear resistance is required for capillary at the adaptation to narrow pitch and low temperature bonding process.

DLC coated single crystal ruby capillary developed by our company ahead of other companies achieves 3 times the abrasion resistance compared to the case without coating. Reduction od capillary change frequency provide benefits such as reduction of maintenance time, increasing controllable machine number, improvement in productivity, and contributes to increase your profits.

DLC Coating

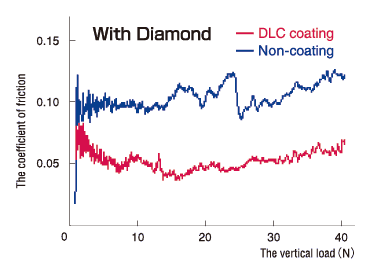

Since wear resistance increased three times, usage of capillary also increased threefold. Stable CD form of capillary enables improvement in bonding ability.

Since DLC coated ruby capillary has low coefficient of friction surface, the dirt rarely adheres to the capillary's tip. This coating achieves longer life span of capillary.

At the bonding process, the dirt which adheres to the capillary's tip is one of the factors to reduce the capillary life span. Since coefficient of friction is decreased by the DLC coating, adhesion of durt on the capillary tip is reduced.

Catalog

Ruby Capillary

Standard Type Catalog

BPP:100μm∼

Ruby Capillary

Fine Pitch Series Catalog

BPP:60∼100μm

Ruby Capillary

Uitra Fine Pitch Series Catalog

BPP:40∼50μm

Custom-made

Please fill the blank space of custom-made order sheet.