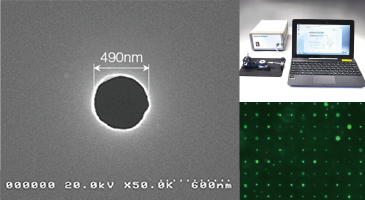

Orbray's fine hole processing technology has evolved from micron-to nano-level order. By applying the polishing technique we use for our diamond stylus, we developed an in-house diamond micro drill for precision drilling. Moreover, we introduced cutting-edge femtosecond laser processing technology. By combining the femtosecond laser and diamond micro drill, we have established ultra-precision hole processing from micron- to nano-level order.

These ultra-fine holes are mass-produced as nozzles for microfluidic devices. Minute volumes of various liquids and gasses can be precisely controlled.

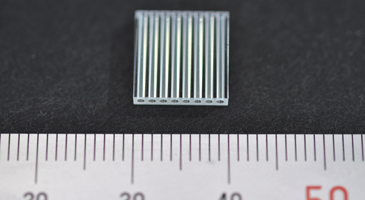

For the biomedical field, where research has been active in recent years, we have developed and produced a cell membrane monitoring device which can be used to observe micron-order cell membranes. Although it is hard to handle micro-sized samples, this device uses suction to fix membranes to a micro-hole array, enabling them to be handled quantitatively.

We can respond to a variety of requests, such as the development of parts for industrial and laboratory analysis equipment that require micro-holes. Our company's core technology (cutting, grinding and polishing) has been built on processing hard materials, and we can offer you the best solutions for materials such as silica glass, sapphire and ceramics.

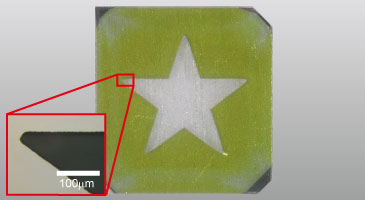

Laser Drilling

In addition to cemented carbide, our company also specializes processing fine ceramics such as alumina, zirconia, and single crystal ruby.

In cases where processing is difficult with conventional methods, grinding and polishing is sometimes done with diamond abrasive grains or by ultrasonic or electrical discharge machining. However, these methods can not maintain the inherent physical properties of ceramics, so challenges arise where the required precision can not be met or processing time is too long.

At our company, we've developed a technology that can process fine ceramics by combining our personal technology with a high power focused laser and a special optical system.

In drilling processing, we have established high precision micro perforation technology that can machine materials such as ceramics, alumina ceramics, silicon nitride and aluminum nitride.

As an example, when drilling a φ 0.05mm hole in a material with t = 0.5 mm, a straight via hole is achieved with a high precision aspect ratio (ratio of hole diameter to plate thickness) of 10 and hole tolerance ± 2μm.

Additionally, there are no debris around the hole, the machined surface is smooth, and secondary machining is not required.

Precision processing of holes

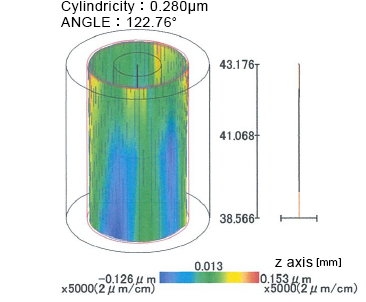

Cylindrical processing

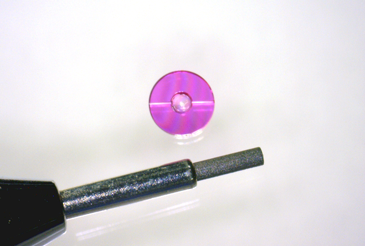

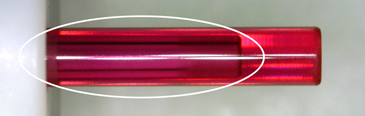

Although, at first glance, a zirconia ferrule looks like just a simple ceramic cylinder, our cylindrical processing technology is indispensable for machining and it is a very complex processing technology.

The outer diameter is ground and polished on a submicron level, and it can meet a tolerance of ±0.0005mm.

Boring Processing

Drilling a cylindrical hole, or enlarging a drilled hole.

We can perform high precision processing with our own internal machines and special tools.

Inner diameter processing

The difficulty in bore processing is that, for example, when the work material is a hard material such as ceramic, it can not be easily processed with a tool such as a blade, so the cylindricity and the surface roughness of the inner diameter become uneven.

We have been pursuing manufacturing using our know-how to get nanometer level accuracy while still maintaining roundness and staying true to the characteristic nature of the material.

Although the typical application differs for each product, as an example, one product with one or more φ0.1 to φ1.2 mm through holes in the center can be used in parts such as liquid injection nozzles (for pesticide spraying, etc.).

With our processing technology, it is possible to machine a φ0.01 mm hole in various ceramic materials.

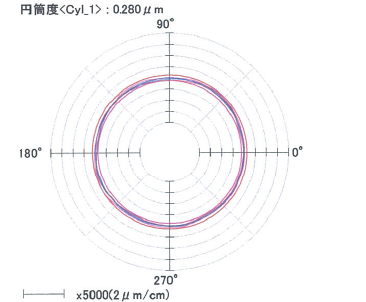

Cylindricity:0.280μm Coaxiality:0.350μmRoundness:0.190μm

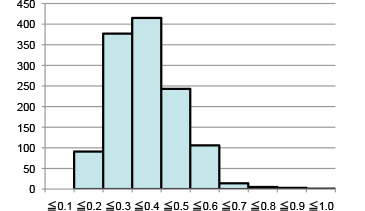

| coaxiality (μm) | |

|---|---|

| MAX | 0.97 |

| MIN | 0.12 |

| AVE | 0.35 |

| σ | 0.114 |

| Cp | 1.908 |

| n | 1,255 |

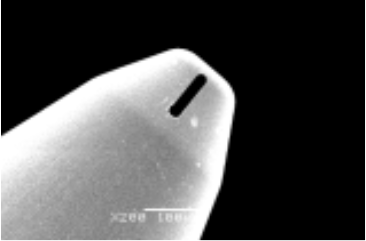

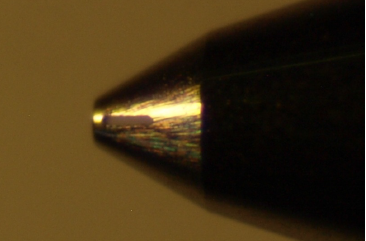

Oval hole processing

Elliptical hole is machined by applying laser processing and grooving processing.

Oval-shaped via hole with a width of 0.02mm x length of about 0.1mm.

Material: Tungsten carbide