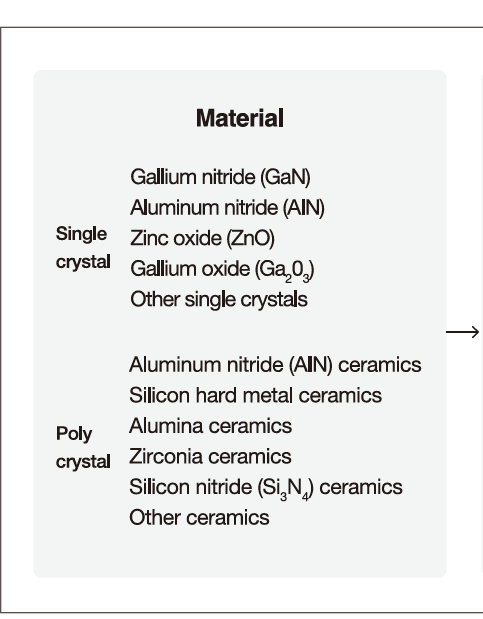

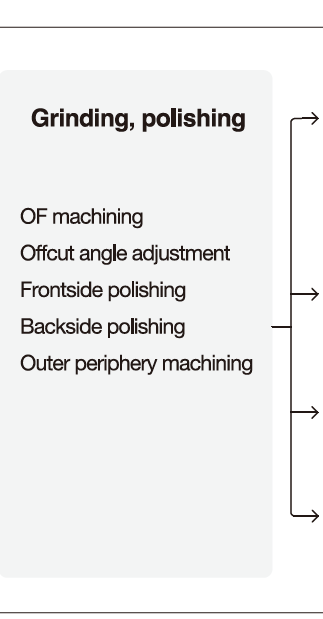

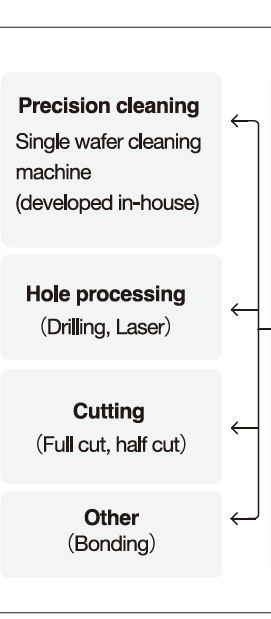

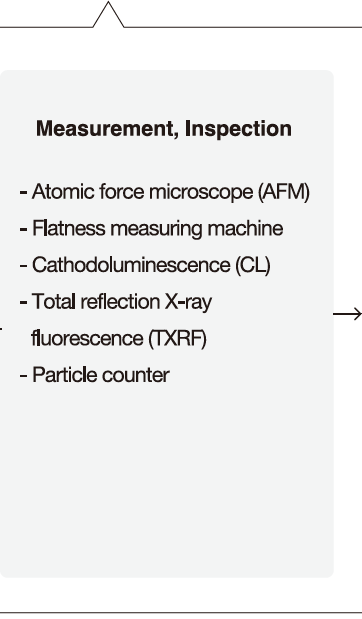

Utilizing our polishing technology for high-hardness sapphire material, we do contract polishing and grinding of various materials, such as aluminum nitride ceramics, alumina ceramics, and zirconia ceramics. In addition, we can polish single crystals such as gallium nitride (GaN), aluminum nitride (AlN), zinc oxide (ZnO), gallium oxide (Ga2O3), and yttrium aluminum garnet (YAG). Please feel free to contact us with any request, as we can also process materials other than those listed. We also offer fine hole processing (drill/laser processing), bonding (atomic bonding), backside polishing, and full cutting (groove processing). For single-crystal materials, we support wafer processing, such as orientation flat processing and off-angle adjustment.

* We have a variety of other processes available; please contact us.

High Flatness Polishing Processing

| Processing | Processing equipment | Work | Processing accuracy | |

|---|---|---|---|---|

| Maximum size | Maximum thickness | |||

| Cutting | Peripheral blade cutting machine | □200mm | 5mm | ±0.5mm |

| Inner peripheral blade cutting machine | φ8 inch L150mm |

10mm | ±0.1mm | |

| Wire cutting machine | φ8 inch L300mm |

3mm | ±0.03mm | |

| Dicing machine | □150mm | 1.5mm | ±0.02mm | |

| Surface grinding | Surface grinder | 600×300mm | 200mm | 0.03mm |

| Horizontal grinder | φ5 inch | 50mm | ±0.01mm | |

| Vertical grinder | φ8 inch | 100mm | ||

| Double-side lapping machine | φ12 inch | 30mm | ||

| Outer periphery grinding | Cylindrical grinder | φ8 inch | 300mm | ±0.01mm |

| Centerless grinder | L150mm | 20mm | 0.01mm | |

| NC machine | φ300mm | Depends on the processing (please contact us) | ||

| Surface polishing | Double-side lapping machine (Diamond/CMP) | φ12 inch | 30mm | ±0.005mm |

| One side polishing machine | φ6 inch | 50mm | ||

| Drilling | Micro drilling | φ12 inch | 10mm | φ±0.25mm |

| Laser processing machine | φ6 inch | See below | ||