In the 1960s, the electric discharge machine was only used for molding because it was an expensive machine. However, it became a big topic of interest for its use in the mass production of cemented carbide watches.

Since that time, our company has advanced our precision processing technology by integrating our core technologies “cutting, grinding and polishing” with advanced technology, and continues to do so today in order to do super precision machining for ultra precision products.

By combining electric discharge machining technology with advanced machining technology cultivated through Orbray's in-house production facilities and tool manufacturing, we support die and mold parts and various high precision machined parts.

We also offer consultations for replacing parts with various special materials such as sintered diamonds, carbide, ceramics, etc. to reduce running costs and prolong service life.

Electric Discharge

When a lightning strike occurs, a tree falls down and burns. This is due to 'discharge', which is the surge of current that flows between the lightening and the ground. In this discharge, a high amount of energy is consumed in a short time.

By utilizing this phenomenon, material can be dissolved and evaporated on a product's surface. Furthermore, the high pressure generated makes the molten area disperse, which results in a dimple on the product surface. By applying high voltage to a tool and bringing it closer to the surface of a material, an electrical discharge occurs on the surface of material, removing the material and causing a dent. By making this dent continuously, we are able to machine the product.

EDM and the wire electrical discharge machine can be used in the processing of hard materials such as cemented carbides, conductive ceramics, and sintered diamond, as well as for complicated shapes, piercing small holes, and creating slits.

Machining

Cutting is a necessary process in metal working. In the past, it had to be carried out by manually replacing the cutting tools, but today, machining centers are widely used for automated machining at the manufacturing site.

Machining refers to automatic cutting processes by the machining center, which automatically exchanges the tools by computer control.

In addition, the value of the coordinate position (XYZ axes) where the tool moves during processing and the speed at which the tool moves is controlled by numerical data called NC data. Although this numerical data can be input directly to the machine tool, it takes time to input manually when the processing method and shape are complicated.

Therefore, we create the numerical data on a PC using 3-D CAM, and then transfer the data to the machine tool. Since Orbray uses a 3-axis linear motor driven system, it is possible to perform high precision machining according to the numerical values made with 3-D CAM.

Our Processing Machine

- Wire-Cut Electric Discharge Machine

- NC Electric Discharge Machine

- Linear motor driven precision machining center & 3D CAM

Processing Examples

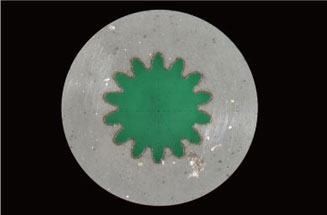

Wire-cut electrical discharge machining

Suitable for tapering or four-sided processing of conductive material such as cemented carbide.It is possible to process wire electrodes diameter Φ0.02 ∼ Φ0.1

Material :SKD(HRC60) Size : φ1.06

Processing of R = 0.01 using a wire electrode diameter Φ0.02.

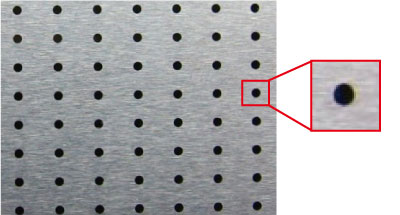

NC Electric Discharge Machining

Φ40μm hole processing on carbide is possible.

(Aspect ratio 10)

Equivalent processing is also possible for conductive materials.

Φ40μm hole drilling on carbide

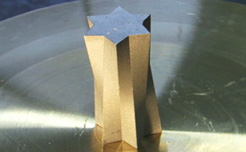

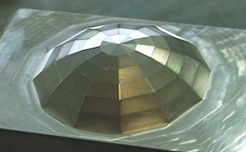

Linear motor driven precision machining center & 3D CAM

3-D Processing Examples

Die & Mold Processing Example

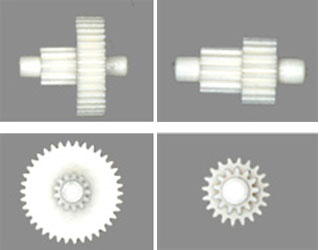

Resin gear mold for micro-motor

Module = 0.065

Material: POM5