What is a DC coreless motor?

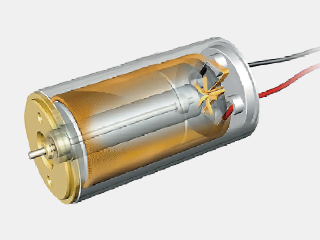

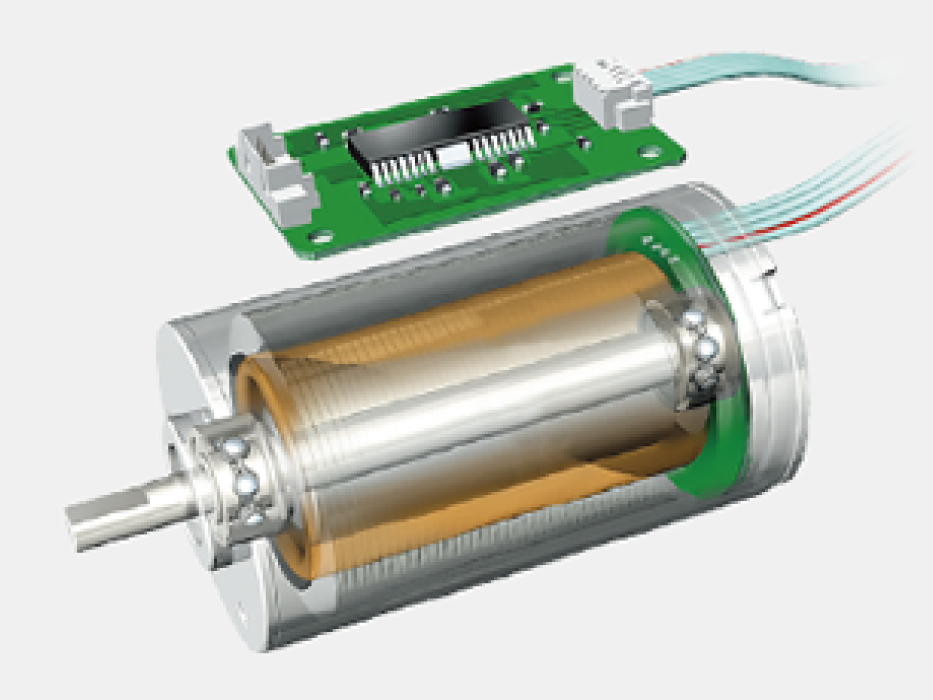

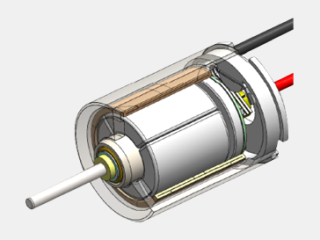

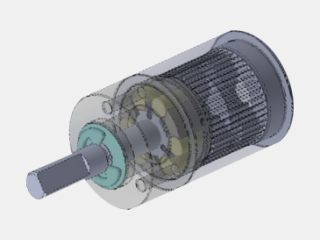

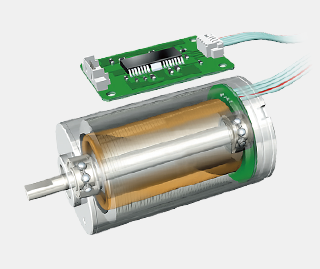

DC Coreless motors, as the name suggests, have no iron core in the rotor. Instead, a copper wire winding in a basket configuration (coil) rotates around the outside of a cylindrical magnet. Three major features of coreless motors are as follows:

- Not having an iron core in the rotor prevents cogging caused by magnetic induction; hence the rotation is smooth, with minimum noise and vibration.

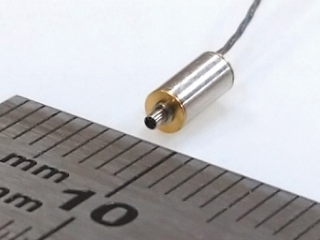

- By utilizing rare earth magnet with high magnetic properties together with a rotor in basket configuration, miniaturization of the motor itself becomes feasible.

Product line-up

Coil winding

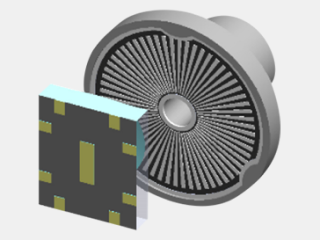

A unique feature of Orbray's coreless DC motor exists in its coil windings.

To gain better coil space factor, an auto-winding machine was developed in-house to achieve high winding density and accurate alignment. The auto-winding technology allowed us to raise the motor torque constant and also lower the current consumption concurrently. Nicely balanced coreless coil winding with no cogging feature allows for smooth rotation, low moment of inertia, and miniaturization of the motor body. Such super thin wire winding technology know-how makes it possible to create a brushless motor that is less than 1mm in diameter.

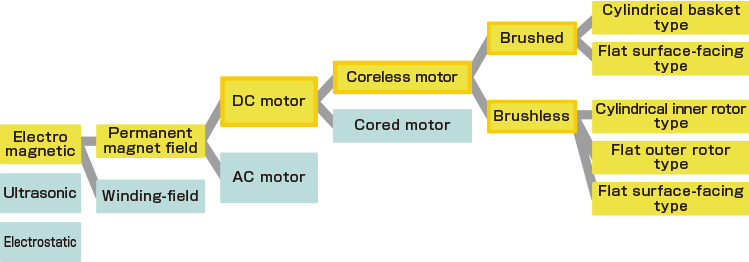

Orbray DC Coreless Motor Types

The Advantages of Orbray DC Coreless Motors

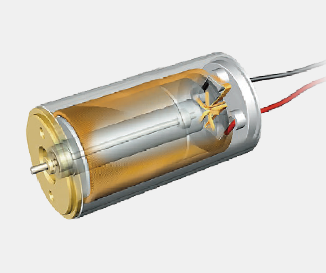

Orbray's brushed and brushless motors are both coreless types. Compared to cored motors, the advantage of coreless is that there is no cogging, which allows for quick response to micro adjustments in voltage and current, high torque constant, and a quieter motor. Another strong point is in the low electric noise, which is the most important requirement for use in camera lens drivers. The gold alloy that Orbray employs for polarity switching contacts lowers electrical noise to the utmost limits, and is a "must-have" technology in professional video cameras.

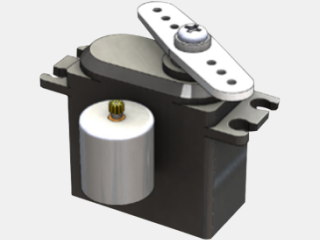

In the field of radio control servos, typically brushless motors are not used because the magnet rotor has a slower response time. To solve this issue, Orbray designed a brushless RC servo using an inner rotor type motor. However, simply changing from an outer rotor type to an inner one does not make it faster by itself. In addition, the rotor diameter was decreased to control the moment of inertia, the stator side coil thickened to increase current, the number of windings increased, and the air gap between the stator and rotor made as small as possible. These adjustments all served to increase the torque.

This raised torque shortened the mechanical time constant to 5.2ms, which is faster than that of the lightweight coil rotor type, impressing RC enthusiasts who use RC servos in high-end racing aircrafts.

Orbray’s DC micro motors have reached a diameter as small as 1mm, which makes them useable in catheters that are inserted into arteries. In 2014, Orbray succeeded in the development of a record small 0.6mm diameter DC motor, and will continue to take on the challenge of making microminiature motors for years to come.

Recommended Applications

Considering the above mentioned features, the most suitable applications for Orbray motors can be seen:

Fast response

- Video camera lens drive

- Surveying instrument

- Industrial Servo

- Robot

Microminiature motor

- Endoscope

- Catheter ablation

- Endoscopic Ultrasound

- Micro surgery

- Micro Robot

Quietness (mechanical, electric)

- Audiovisual equipment

- Surgical drill

- Communicaton robot